Hidden from view and never requiring maintenance, it’s easy to forget that wheel bearings don’t last forever. But how do you know when there’s a problem? What are the symptoms of a bad wheel bearing that you should look out for, and what do they cost to replace?

What Will It Cost To Replace A Bad Wheel Bearing?

The costs vary wildly – from about $200 to $1,000 per axle, with an average of about $400 – depending on the vehicle and type of bearing that needs to be replaced.

The cost of replacement is largely determined by the cost of the parts and how labor-intensive the job will be. This will vary depending on the type of wheel bearing assembly:

Serviceable hub assembly – this type of wheel bearing assembly is neither labor-intensive nor parts intensive, and best of all, the parts are usually inexpensive, so you could probably get away with a bill of between $100 to about $300.

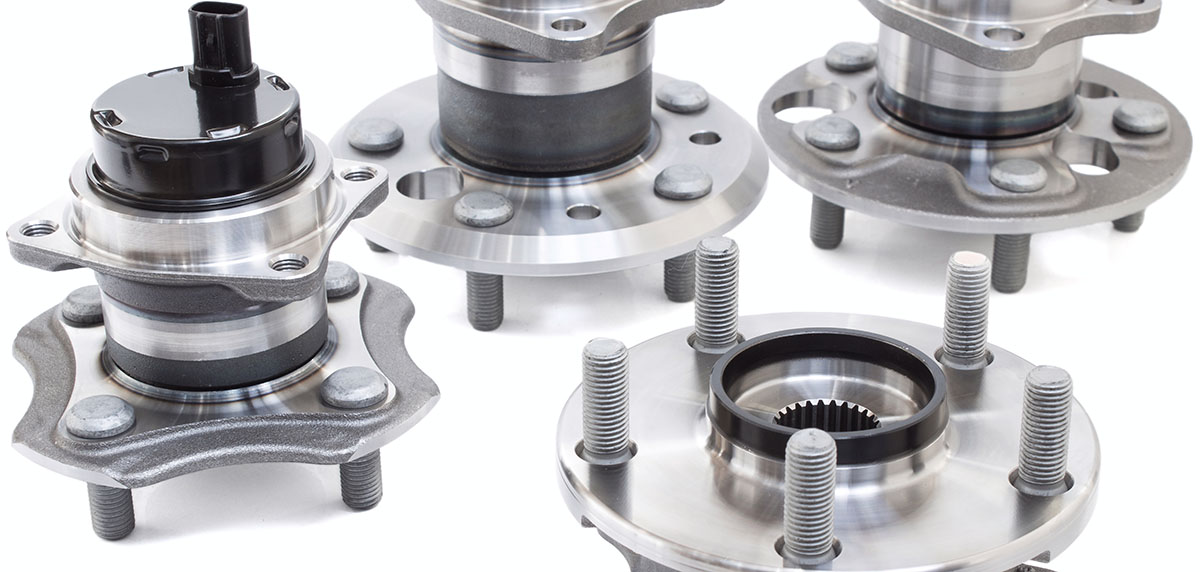

Non-serviceable hub assembly – this type of wheel bearing necessitates that the complete hub be replaced. So while the replacement is not labor-intensive the price of the parts could be quite costly, depending on the type of vehicle. The total cost to repair should range from about $400 to $700.

Non-serviceable hub assembly with a press in bearing – this is the most expensive wheel bearing to replace. It is labor-intensive – the repair should only be carried out by a professional mechanic or shop – and the parts are costly. This type of repair could set you back more than $800, depending on the type of vehicle.

The Wheel Bearing Basics

Before answering the vital questions on the subject of this article, it is important to take note of the following:

- Wheel bearing replacement is best left to the professionals;

- Each wheel is supported by a wheel bearing;

- Wheel bearings usually fail individually, and therefore, do not necessarily need to be replaced in sets;

- Wheel bearings come in different sizes and types to suite a wide range of applications.

All bearings consist of a rolling element – a set of balls in the case of ball bearings, or cylindrical rollers in (taper) roller bearings, held together by a metal separator and housed in metal inner and outer races. These can also be sealed against dirt and water ingress. However, wheel bearings are safety critical components that have to contend with significant radial and axial loads, and are therefore designed specifically for this purpose.

Note: All wheel bearings weren’t created equal. So make sure you pick one specifically for your car.

Driven and steering wheels have different forces being exerted on them: Front steering wheels not only have to contend with radial loads but, in steering the vehicle, they are also subjected to axial loads as they coax the vehicle into changing direction. Rear wheel bearings, on the other hand, primarily need to carry radial loads. For these reasons, the clear delineation of bearing types by application.

The Different Types Of Wheel Bearing

Before front-wheel-drive vehicles became popular it was common practice to fit ball bearings to the rear (driven) axle and taper roller bearings to the front (steering) wheels. This was/is done to draw on the unique qualities of each type of bearing in the specific application.

The taper roller wheel bearing – slightly more expensive, these are usually used in applications that are subjected to high axial loads. They are also less sensitive to slight misalignment, making them ideal for front wheel applications on rear wheel drive cars.

Double-row deep groove ball bearings – because of their lower rolling resistance they are more efficient than roller bearings, while the support offered by the deep groove enables them to withstand axial loads approaching the carrying capacity of taper roller bearings. This is why most modern front-wheel-drive cars use them in the front wheel assemblies. Typically these assemblies comprise a pair of deep-groove ball bearings in a common housing, usually sealed against dirt and water ingress.

Single-row deep groove ball bearings – with less axial loading to contend with, wheel bearings fitted to the rear axle are typically single row ball bearings. This reduces friction and cost without compromising performance or durability.

After hundreds of years of development, wheel bearings are widely considered to be maintenance free. This is no mean achievement with the average wheel bearing completing about 75 million revolutions over 100,000 miles. Currently the life expectancy of such a wheel bearing is about 80,000 miles, with very few making it past 120,000-miles.

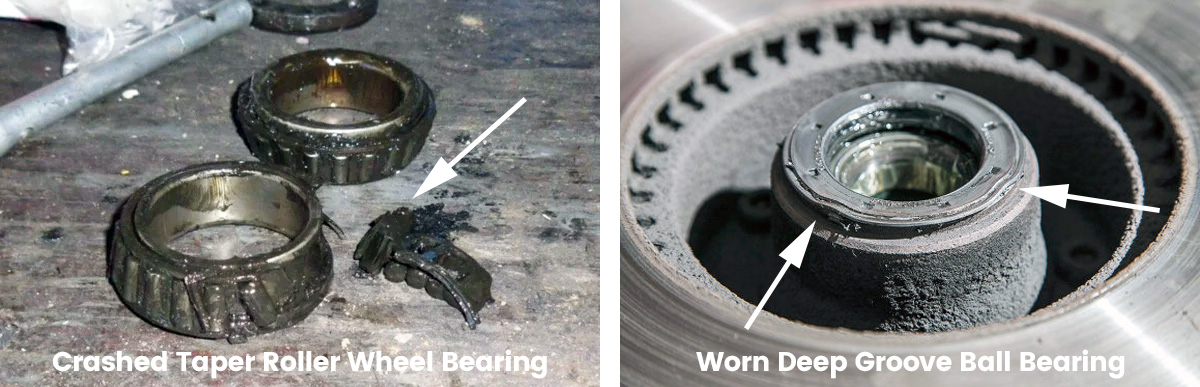

The Symptoms of a Bad Wheel Bearing and What Causes Bearing Failure

Even though you can reasonably expect a wheel bearing to last for at least 80,000 miles there are many reasons why a bearing might fail before that. For example, damage to a wheel bearing can occur as a result of roughly removing a brake rotor to replace it. But, the most common causes include:

- Road damage – any impact from driving through a pothole or colliding with a curb can cause damage, not only to the wheel assembly, but also to the wheel bearing. This damage will usually not result in immediate failure, but will more likely reduce the lifespan of the bearing.

- Adverse driving conditions – prolonged submersion in water or mud could result in these, or other contaminants such as dust or road salt, penetrating the seals and polluting the grease that will eventually lead to bearing failure.

- Car modifications – while fitting a set of stylized wheels may seem like an easy way to personalize your car, it is also a sure way of reducing bearing life. This is particularly true if wider rims with an increase in “offset” are fitted – this will significantly increase the axial load on the bearing.

- Poor quality parts – the manufacturing process to produce a bearing is both precise and costly. Therefore, cheaper bearings are often not manufactured to the best standards, resulting in low-mileage failures.

- Incorrect installation – bearings are precision components that can easily be damaged during installation. Applying force by using any impact tool, such as a hammer, will damage the finely ground surface of the race and/or rolling elements, leading to premature failure.

With so many factors influencing the lifespan of a wheel bearing it is important to recognize the early symptoms of a bad bearing, so that you can take corrective action before being left stranded at the side of the road.

How To Recognize The Early Symptoms Of A Bad Wheel Bearing

Symptoms of worn wheel bearings vary in severity, although the first sign that a bearing is reaching the end of its life is usually an abnormal noise emanating from the wheel. However, given the amount of road noise coming from the tires this is not always easy to detect, often resulting in failure before any action can be taken.

Nevertheless, the following are some of the early symptoms of a possible wheel bearing failure:

- A clicking or popping noise when cornering or making a tight turn – the noise will generally come from the inside wheel when turning. So if the noise is more prevalent, or only present, when turning right, the right side bearing is likely to be the culprit. This can, however, also point to a worn or damaged outer CV-joint.

- A humming or growling noise – while this noise will be present when driving in a straight line, it will get worse when turning to the left or right. Again, the wheel on the inside of the turn will be the defective bearing. This is quite easy to confuse with normal tire noise, so it is important to carry out several direction changes to try and establish a pattern.

- A metallic grinding noise – this could indicate damage to a roller, ball, or race. Again, the noise is normally heard when there is a change in load during cornering, with the faulty bearing located in the inside wheel.

- Wheel vibration andor runout – this would generally indicate a bearing that has sustained extreme mechanical damage. Before a wheel bearing reaches this stage it would have presented with one or more of the symptoms above. This is more likely to be a symptom of an out-of-balance wheel assembly.

- Abnormal or uneven tire wear – again, while an extremely worn bearing can cause abnormal tire wear, it typically points to other components; such as worn or damaged dampers, wheel alignment, or improper tire inflation.

- The car pulls to one side when applying the brakes – as with the point above, this would only occur if the bearing was badly damaged. It is more likely to be caused by a problem with the caliper or wheel cylinder.

The best advice for replacing bad wheel bearings is probably not to wait until they get so bad that they cause consequential damage to other parts, such as the braking system. By getting to know your car, in particular what noises are normal, you will be able to pick up the symptoms of a bad wheel bearing that much quicker.

We do an efforts to find, research and recommend the best products. So, we may receive commissions from purchases that you make after following the links in our product reviews.