Home \ Shop \ Engine & Efficiency \ Brake Pads

The Best Brake Pads in 2025 (TOP6 Review)

To ensure braking safety & performance is not worth saving on brake pads

- 1. The 6 Best Brake Pads Review

- 2. BOSCH QuietCast Ceramic Brake Pads (BC1293)

- 3. TRW Automotive Brake Pad Set (TPC1293)

- 4. WAGNER Ceramic Disc Brake Pad Set (QC1293)

- 5. ACDELCO Gold Ceramic Brake Pads (17D1222CH)

- 6. POWER STOP Z23 Evolution Brake Pads (Z23-1293)

- 7. BREMBO Front Brake Pads Set (P83117N)

- 8. What Defines the Best Brake Pads?

- 9. Significant Features When Buying Brake Pads

- 10. What are The Best Brake Pad Brands?

- 11. What are the first symptoms of worn-out brake pads?

- 12. Do ceramic brake pads increase the wear on rotors?

- 13. How should brake pads last?

- 14. Do I need to change all the brake pads of the car at the same time?

- 15. At what thickness should I replace brake pads?

Brake pads are probably one of the least thought about components on a motor vehicle. Hidden from sight, the average driver almost certainly never gives them a second thought – just assuming they will always work as expected. And so they do.

However much like a car’s tires, brake pads are subjected to wear and tear, and therefore require periodic replacement. The good news is that there are literally thousands of makes to choose from; the bad news is that there is much more to a brake pad than its ability to bring the car to a stop.

The best brake pads have to perform well in all climatic conditions, absorb and disperse heat, all while offering a good mileage without generating excessive noise and dust.

So, with so many brands and types to choose from, it is easy for the consumer to become overwhelmed, but by using this guide it should be relatively easy to find the best brake pads to suit any driving style and vehicle, at an acceptable price.

The 6 Best Brake Pads Review

PROS

- These pads have a great lifespan

- Made with using aerospace technologies

- Provides a highly efficient braking

- Works quietly thanks to a special noise reduction technology

- Comes as a kit for easy installation

CONS

- No significant downsides

MAIN CHARACTERISTICS

BRAND

BOSCHPOSITION

FrontMATERIAL

CeramicMODEL

BC1293WEIGHT

3.5 lbPRICE RANGE

$$$

What are you looking for in a brake pad set? Longevity? Durability? Quiet operation? If these factors are important to you, then this is an awesome pick for you. This front brake pad set comes from the Bosch brand and comes in ceramic material. It ensures excellent stopping ability. It also allows a noiseless operation of your vehicle and prevents dust gathering. The noise protection offered by this brake pad is due to its multilayer shim that also increases its strength. It possesses a protective layer that ensures the longevity of the rotor life and pad. Finally, it comes with a synthetic lubricant that comes in handy for the functionality of the brake. In line with the 2025 copper-free legislation, this brake pad set comes in a copper-free ceramic material. With this brake pad set, you are assured of quiet operation, longevity and durability, which are traits typical of Bosch products. Another interesting thing about this brake pad set is that it comes with a complete hardware kit.

PROS

- Good for intensive braking in heat conditions

- Built to last, thanks to a premium ceramic compound

- Ensures high braking performance

- Advanced design for effective heat dissipation

- This model have many variations for a wide range of car brands (Use Amazon "Check Fit" option)

CONS

- Quite expensive

MAIN CHARACTERISTICS

BRAND

TRW AutomotivePOSITION

FrontMATERIAL

CeramicMODEL

TPC1293WEIGHT

4.25 lbPRICE RANGE

$$$$$

You have a big decision to make in choosing the right brake pad. It will be attached to a vehicle that conveys valuable people and cargo, so you want to make the best decision. This brake pad set fits the Lexus ES350: 2007-2018, Lexus ES300h: 2013-2018, Toyota Camry: 2007-2018, and Toyota Avalon: 2008-2015 (Use Amazon “Check Fit” option to confirm fitment for any car brand and model). It comes in ceramic material and is positioned at the rare of vehicles. It comes with all relevant hardware accessories for ease with the installation. TRW is one of the leading brands when it comes to braking systems and technologies. The brand has a lot of affiliations with leading vehicle manufacturing companies globally. Be assured that you get quality, safety, durability and performance from this brake pad set. TRW ceramic brake pads are designed with friction formulations that ensure noise, vibration and harshness (NVH) are eliminated. This brand also reduces wheels’ accumulation of dust. This brake pad set meets up with Original Equipment (OE) standards and has undergone a series of tests in the lab as well as in the real world. Another interesting thing about this ceramic brake pad set is that it delivers faceless performance. This means that it curbs the heat that is associated with using brakes in heavy traffic.

PROS

- Gives quiet braking due to a noise reduction system

- These pads have good cost-effectiveness

- Designed for long-lasting good braking

- Comes with premium quality accessories for specific applications

- Fits a lot of cars (use "Check Fit" on Amazon)

CONS

- Durability not of the highest level

MAIN CHARACTERISTICS

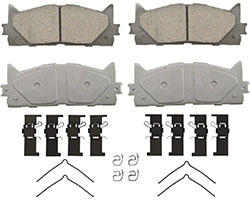

BRAND

WAGNERPOSITION

FrontMATERIAL

CeramicMODEL

QC1293WEIGHT

4.13 lbPRICE RANGE

$$

This brake pad set comes in ceramic material and is positioned at the rare of a vehicle. It is designed in a way that enhances braking performance and reduces the chances of brake rotor wear. It also reduces the accumulation of dust. This brake pad set also comes with relevant premium hardware. Another interesting feature of this brake pad set is that it comes in a formulation design that evaporates heat which ensures long-term friction and reduction in brake fade. This design also helps to spread heat, vibration, and sound which reduces noise levels. The Wagner QC1293 ceramic disc brake pad set boasts of a one-piece design with IMI technology that integrates backing plate, friction material and insulator into the brake pad. A very important factor that is considered by anyone who desires to go for a brake pad set is how effectively it deals with noise. This brake pad brand effectively does this by spreading out heat sound and vibration.

PROS

- Easy to install and fits perfectly

- Enhances quiet operation of the brakes

- Comes in heat dissipation design for better operation at high temperatures

- Passes SAE J2784 test for braking effectiveness

- Long-lasting ceramic material used

CONS

- No significant downsides

MAIN CHARACTERISTICS

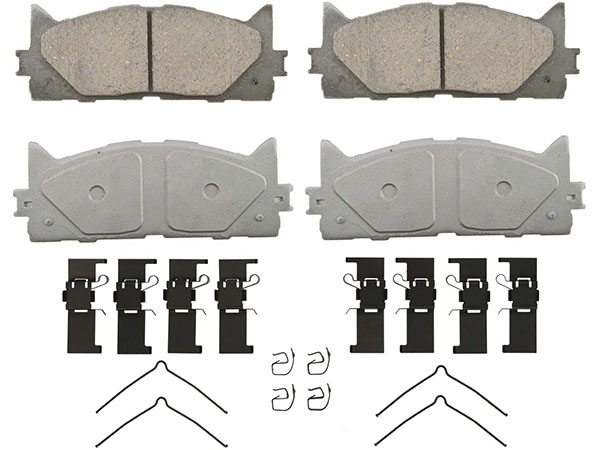

BRAND

ACDelcoPOSITION

FrontMATERIAL

CeramicMODEL

17D1222CHWEIGHT

4 lbsPRICE RANGE

$$$

This brake pad set is designed in such a way that it meets up with the requirements of fit, form and function. Another very important feature of the ACDelco Gold 17D1222CH ceramic front disc brake pad set is that it is a good choice for general-purpose vehicles. This brake pad set also comes in ceramic material and is positioned at the rare of a vehicle. This brake pad set is made in such a way that it helps to prevent premature wear and corrosion. Its ceramic formulation is such that it contains a little amount of metal and this ensures braking power high in quality. It also comes with shims that reduce noise to the barest minimum. These shims also help to reduce vibration and braking harshness. The organic formulas that make up this brake pad set ensure safety and reliability for vehicle applications. This brake pad set possesses a stamped backing plate that gives room for proper movement of the pad. This helps to reduce noise, brake vibration, and provides protection from premature wear.

PROS

- Long-lasting carbon fiber infused ceramic material

- Comes with an extended list of accessories for easy installation

- Fits nicely for high-intensity braking operations

- Durability at the high level

CONS

- They should be quite expensive for general-purpose cars

MAIN CHARACTERISTICS

BRAND

Power StopPOSITION

FrontMATERIAL

CeramicMODEL

Z23-1293WEIGHT

4.05 lbPRICE RANGE

$$$$$

The braking power of a brake pad set is another crucial factor that should be put into consideration before going for a brake pad set. This set of brake pads offer superior and excellent braking power and are great choices for you. They are made from carbon-fiber ceramic formulation and this offers really good braking performance. They are positioned at the rare of vehicles. These sport brake pads have been designed to bring an upgrade to the braking power of practically everything you drive. They also reduce the accumulation of dust and possess a backing plate that is coated with powder. This helps to increase longevity by resisting corrosion and rust. These brake pad sets are noise-free and lower the possibility of fade. They also come with premium hardware kits that come in handy when applicable. Power Stop Z23-1293 Z23 Evolution sport brake pads come with lubricants which are included in every brake pad set. These brake pads come with excellent shims that enhance noise-free braking.

PROS

- High-performance brake pads with good heat dissipation technology

- Built to work effectively under high braking intensity

- Works best when heated thanks to the alloy steel characteristics

- Fits a lot of cars on the North American market (use "Check Fit" option on Amazon)

CONS

- Quite noisy thanks to a construction of metal

- Durability isn't at the high level

MAIN CHARACTERISTICS

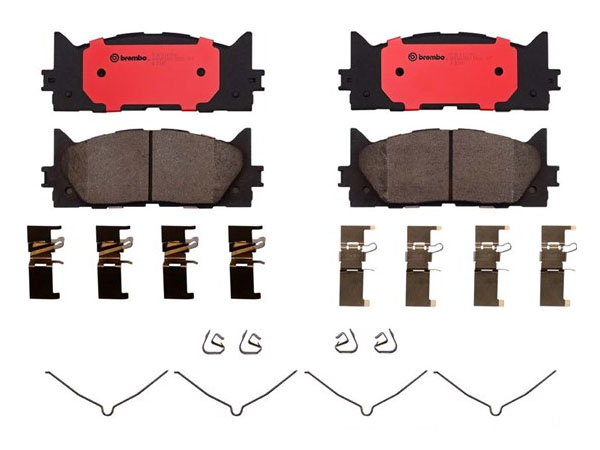

BRAND

BremboPOSITION

FrontMATERIAL

Alloy SteelMODEL

P83117NWEIGHT

2.06 lbPRICE RANGE

$$$$$

The Brembo P83117N front disc brake pads, unlike the preceding brake pads, is made from alloy steel and is positioned at the front of vehicles. This brake pad set is uniquely designed for the North American market. There is not much to be said about this brake pad set other than it possesses a shim that avails quiet, comfortable smooth braking and clean wheels.

What Defines the Best Brake Pads?

Although the original equipment brake pads installed by the manufacturer have been meticulously engineered, when deciding on the best replacement brake pads the weight and type of vehicle as well as how it is used, play an important role in the selection.

While there are many different compounds and friction materials used for brake pads, the best brake pads can be divided into three main categories defined by the material type, each with its own advantages and disadvantages:

1. Organic Brake Pads.

At first, brake pads made use of asbestos fillers because of their excellent heat-absorbing properties. However, after the material was classified as hazardous, manufacturers began developing non-asbestos organic (NAO) friction materials – commonly known as organic brake pads – to fill the gap.

The best organic brake pads, fitted as standard to most new vehicles, contain a mixture of glass- or Kevlar-fibers and fillers such as rubber and carbon, bound together with resin. This construction produces less dust than alternate metallic friction material and is generally reasonably priced.

Unlike performance brake pads, which are predominantly used in heavy and high-performance vehicles, organic brake pads operate at the lower temperatures typically encountered in everyday driving. The organic materials used, also ensure quiet operation with minimal wear and tear of the brake rotors.

Because of their composite nature, organic brake pads do however have a few disadvantages:

- They display higher wear-rates and require more frequent replacement

- The compressibility of the material also slightly reduces “pedal-feel”, often appreciated by performance-orientated drivers

- As mentioned, they cannot sustain high temperatures, functioning best within a narrower heat range at lower thermal loadings

So, while organic disc-brake pads are a very good all-round solution for everyday driving, there is a growing demand for friction materials that can withstand a wider range of temperatures to cope with heavier payloads and more aggressive braking maneuvers, thus the increase in popularity of the metallic brake pad.

2. Metallic Brake Pads.

The best semi-metallic brake pads commonly referred to as “metallic brake pads”, are made up of between 30 to 70 percent metals, which could include copper, iron, steel, and any number of special alloys. These metals are bound together with various fillers that usually include graphite as a lubricant. By adjusting the composition, manufacturers of the best metallic brake pads have developed products capable of supporting a wide variety of uses – from daily commuting to circuit racing.

By including metals to dissipate the heat generated during braking, these brake pads are well suited to applications that demand heavier braking. They are also less compressible than organic materials, giving the driver better feedback.

Still, there are a few drawbacks to metallic brake pads:

- The pads produce more dust

- Brake rotor wear is increased

- They are slightly more expensive than organic brake pads but cheaper than ceramic parts

- They emit more noise than their ceramic or organic counterparts

And with the rollout of quiet electric and hybrid vehicles, noise-suppression is becoming ever more important, hence the increase in demand for ceramic brake pads that emit significantly less noise.

3. Ceramic Brake Pads.

While there is a school of thought that argues that ceramic brake pads are merely high quality organic parts, the best ceramic brake pads do in fact rely on alumina, or aluminum oxide, boron carbides and silicon carbide (amongst others) to enhance their performance. Ceramic brake pads also usually contain fine copper strands to improve heat dispersion – although by 2025 this will be banned entirely.

The best ceramic brake pads boast several advantages over organic or metallic equivalents:

- Because ceramics generate a frequency beyond the human audio-range they are extremely quiet in operation

- These pads produce almost no dust or other residues

- The superior thermal stability of the material means that brake performance is maintained over a wide range of operating temperatures

The only real downside to fitting ceramic brake pads is the slight on-cost, which has to be weighed up against their benefits.

Despite the importance of the type of brake pad material in defining the overall characteristics of the brake system, the wide array of different brake pads available on the market allow consumers to select pads with features that best suit their requirements.

Significant Features When Buying Brake Pads

When shopping for the best brake pads it is important to compare the features claimed by the various manufacturers: By selecting replacement brake pads that best meet specific requirements, consumers have an opportunity to optimize braking performance.

Brake Pedal Feel

When applying brakes, drivers expect the retardation of the vehicle to be relative to the pedal effort exerted. As eluded to earlier on, brake pad compounds play a critical role in achieving this pedal feel:

- Organic brake pads are more compressible resulting in a softer pedal.

- Metallic and ceramic materials yield less than organics, thereby providing a firmer brake pedal.

Operating Temperature

The coefficient of friction (COF) is what determines the brakes’ ability to slow the vehicle, and the COF is dependent on the temperature of the brake pads.

Hence, driving style, vehicle type and size, and operating environment are key factors when choosing brake pads. Under everyday driving conditions, brakes can be expected to get up to 400 degrees, with standard pads capable of coping with short bursts of higher temperatures without fading.

However, towing, and high-performance street- or track-driving can see temperatures exceed 1000 degrees, which would require materials specifically engineered for these conditions.

Completeness of the Kit

With many brake pad replacements being performed by DIY enthusiasts it is important that the brake kit contains all the parts required to easily perform the task.

See also: Best Brake Fluids For Car

It is also important to note that the best brake pad sets are usually sold per axle. However, with some manufacturers supplying full sets, covering front and rear axles – knowing what is in the kit is vital.

Although not normally viewed as a feature, it is nevertheless important that brake pads are correctly labeled.

Classified as safety critical, and containing materials that are potentially harmful to the environment, brake pads have to meet certain standards and be clearly marked as such:

Performance and Environmental Classification

Coefficient of friction classification – a measure of a brake pad’s performance is its cold and hot coefficient of friction (COF). Thus, a two-letter DOT grading that indicates the pad’s COF when cold and hot is printed or stamped on every brake pad. Most aftermarket pads are EE or FF rated. Higher letters represent higher cold and hot COFs, so a GE rating would indicate a pad with a higher COF at low temperatures while a FG pad could be expected to have a higher COF at elevated operating temperatures.

Environmental compliance – the level of environmental compliance is indicated through a system that displays a series of leaves:

- A single leaf indicates that the brake pads meet Level A requirements for cadmium, chromium, lead, mercury and asbestos.

- A second leaf verifies that the materials are classified as Level B, which means they comply with all Level A standards as well as the 2021 limits on copper content.

- Three leaves signify compliance with Level N, which means the brake pads contain less than 0.5 percent total copper, required by the “copper-free” legislation due to come into effect in 2025.

Furthermore, when carrying out a brake pad replacement, it is worthwhile to consider the following:

- Before replacing the brake pads it is important to ensure the brake rotors are not grooved or worn beyond their operating limit. Rotors and brake pads function as a set to deliver the required performance – if the rotors are damaged they need to be replaced before merely replacing the pads.

- If the vehicle is to be used for competition, such as circuit racing, special “performance” racing pads should be used. While these are designed to cope with sustained aggressive braking the friction materials used in these pads require high temperatures to function correctly, so in everyday use they are likely to perform far worse than stock replacement pads.

Although the above guide briefly explains the advantages and disadvantages, of the three key types of brake pad material, and the important features that should be considered, there are dozens of different brands to choose from – making an informed purchasing-decision extremely difficult.

So, as with any consumer product: When in doubt, opt for a reputable brand.

What are The Best Brake Pad Brands?

While an unknown brand offering a cheap brake pad that claims performance and longevity far exceeding that offered by manufacturers of the best brake pads might seem tempting, if it seems to be too good to be true, it probably is.

Here are some brands that have built up a reputation for not only supplying reputable products but also backing them with sound engineering and product support over many years.

Robert Bosch:

More well-known for its electric and electronic products, Bosch, as the largest global Original Equipment supplier also has a well-established line of automotive braking equipment – including the BC1293 QuietCast Premium Ceramic Disc Brake Pad Set.

Often deemed to be the best all-around brake pads because of their extremely quiet operation – largely assisted by the rubber core multilayer shim included in the set – they are particularly popular with owners of Lexus ES300h, ES350, and Toyota Avalon and Camry models.

What makes this product stand out is the use of an advanced aerospace alloy in the patented copper-free ceramic friction formula that is already compliant with 2025 Copper Free legislation.

TRW Automotive:

Another reputable supplier to the automotive industry, TRW Automotive Holdings Corp. has built up a reputation for supplying systems, modules and components to automotive original equipment manufacturers and aftermarket outlets across the world.

Drawing on its years of experience as an OE brake supplier, the company uses vehicle-optimized friction materials developed to eliminate noise, vibration and harshness (NVH) and significantly reduce brake dust in its TPC1293 Disc Brake Pad Set, which is widely regarded as a premium choice when it comes to ceramic brake pads.

Wagner:

While not as well-known as TRW or Bosch, Wagner can trace its history back to the 1890s, with a tried and tested reputation for supplying quality braking solutions that dates back many years.

Meeting the 2021 low copper legislation, Wagner’s ThermoQuiet brake pads, such as their well-priced QC1293 Ceramic Disc Brake Pad Set, use a “one-piece” construction with an integrally molded sound insulator that incorporates the friction material, backing plate and insulator into a single high strength component.

By so doing, the application-specific brake pads significantly improve heat transfer, while reducing noise and vibration. The unique laser-shaped friction-surface also optimizes the pad-to-rotor interface for better braking performance.

ACDelco:

Owned by General Motors, ACDelco does not only make brake pads for its proprietor’s brands but also offers aftermarket parts for non-GM vehicles.

The company’s Professional Range – such as the ACDelco Gold 17D1222CH Ceramic Front Disc Brake Pad Set – is engineered to resist corrosion and premature wear, while offering exceptional performance and low noise.

Independently tested to SAE J2784 standards the ceramic formulation uses less metal and requires no curing (bedding in) after fitment.

Power Stop:

Since 1995 Power Stop has focused on providing safe, problem-free and eco-friendly, performance brake pad upgrades that do not compromise every-day drivability.

The company’s Carbon Fiber-Ceramic Z23 Evolution Sport Brake Pads use a carbon-fiber ceramic material that offers low-dust and -noise operation while resisting fade at much higher temperatures than most OEM pads.

Brembo:

Synonymous with the best high-performance brakes, Italian brake specialist, Brembo S.p.A. has been producing high-performance brake pads since 1961. Specializing in braking systems, the company’s leading research and expertise ensure that all products not only meet the highest quality standards but are also the benchmark in technology.

As such, the Brembo P83117N Front Disc Brake Pads reduce stopping distances while offering quiet and safe braking on a variety of road surfaces and varied climatic conditions.

In achieving this performance the company’s Original Equipment Direct Moulding Pressing Process applies extreme pressure to compress the friction material and ensure maximum bonding with the backing plate. Each pad is then thermally cured to reduce the bed-in time, and brake-fade, at elevated temperatures.

What is more, noise and vibration are reduced through the use of a multi-layer ESE (Elastomer – Steel – Elastomer) red shim which also clearly identifies the pads as original Brembo parts.

Considering the complexity and choices available to the consumer when selecting the best brake pads, there are bound to be many questions, which the following section seeks to address.

FAQs:

What are the first symptoms of worn-out brake pads?

The first signs that the brake pads might be nearing the end of their life is the brake light illuminating in the instrument cluster. Although this is not a wear-indicator – it is actually a warning that the brake fluid is low – it is a sign that the pads have worn considerably and should be checked.

If the pads are equipped with mechanical wear tabs, the next symptom would be a high-pitched squeal, as the tabs come into contact with the brake rotor. These tabs may be substituted with electrical contacts, in which case the instrument cluster will actually have a brake-wear warning light as well as the low-fluid light.

In the absence of a wear-indicator, if the pads get into the resin-zone of the friction material they will emit a grinding noise when the brakes are applied. This requires immediate attention.

When it comes to brake pads, stock replacement parts may often seem to be the simplest solution – if a little expensive – but by following this guide there is no reason that pads should not be safely and cost effectively replaced with aftermarket parts that could better suit the vehicle and operating conditions.

Do ceramic brake pads increase the wear on rotors?

There is no evidence that ceramic brake pads increase the wear on brake rotors. Even though there is sometimes a belief that ceramics are “hard” and must therefore increase wear, like with any braking system, wear is more a function of vehicle type and size, and driving conditions.

How should brake pads last?

As with the question above, brake pad wear is very much a function of vehicle type and size, and driving conditions, but the best brake pads should have a life of between 30,000 and 70,000 miles. Periodic visual inspection is the best way to timeously detect brake pad wear.

Do I need to change all the brake pads of the car at the same time?

No it is not necessary to change the front and rear brake pads at the same time. It is however common to replace both front caliper brake pads at the same time and similarly, the rears.

At what thickness should I replace brake pads?

While there is no hard and fast rule as to at what thickness brake pads need to be replaced, it is nevertheless a good idea to not drop below a pad thickness of about 3 to 4 mm. The primary reason for this is that, there is usually a higher concentration of resin adjacent to the backing plate which can increase wear of the rotor, as well as change the braking characteristics.

We do an efforts to find, research and recommend the best products. So, we may receive commissions from purchases that you make after following the links in our product reviews.