- 1. Why Car Needs Suspension?

- 2. Parts Of The Car Suspension System

- 3. Chassis

- 4. Springs

- 5. Suspension Springs

- 6. Leaf Springs

- 7. Torsion bars

- 8. Air Springs

- 9. Shock Absorbers

- 10. Suspension Struts

- 11. Anti-Sway Bars

- 12. Types of Car Suspension

- 13. Front Suspension

- 14. Rear Suspension

- 15. Suspension Maintenance

Your car’s suspension is one of the main systems that help keep it on the road. If your vehicle has a bad car suspension, you are in for a bumpy ride, but the system does more than smooth things out. The car suspension helps you to control the vehicle and keep it on the road. Let us explore a little bit more about why your car suspension is important, how it works, and the types of suspension systems that you might have in your vehicle.

Why Car Needs Suspension?

If the roads that we drive on were perfectly flat, the car suspension would not be as necessary, but we all know that our roads are anything but flat. One of the main jobs of the car suspension is to keep as much of the wheels in contact with the road as possible. This creates friction between the wheels and road which keeps your vehicle from jumping all over when you hit a pothole. The ability of the suspension to keep the vehicle on the road is as much a part of the vehicle’s performance as the horsepower output of the engine. If it were not for the car suspension, it would be difficult to steer the automobile, and it would make for quite a bumpy ride.

When the vehicle tire strikes a bump or pothole in the road, it causes the tire to move up or down. If the frame of the vehicle were affixed to the axles and wheel without the suspension system, all of the force would be transferred to the frame and eventually to the passengers. This would also put additional strain on the frame and because it to wear out more quickly.

See also: 12 Best All Season Tires

When the vehicle goes over an object or hole, without the suspension system, the wheel would strike the road with a force that could possibly damage the car or cause harm to the passengers. The car suspension absorbs all of this energy and keeps it from being transferred directly to the car and the passengers.

Another thing the car suspension does is that it allows you to accelerate safely, apply the brakes, and take corners without rolling over. The suspension system helps the car to overcome the forces of nature. The ability to handle these forces is described as road isolation, road holding, and cornering. Sometimes, you will see these terms in descriptions of the car’s handling and performance abilities. The most common one you will see is cornering.

Road holding and isolation is the car’s ability to absorb the force of a bump. Road holding is the ability of the car to keep the wheels in contact with the rood surface. Cornering is the ability of the automobile to transfer the weight from the high side of the vehicle to the low side. This allows it to maintain a curved path without drifting off the side of the road. Now, let us see how the car suspension achieves all of these things.

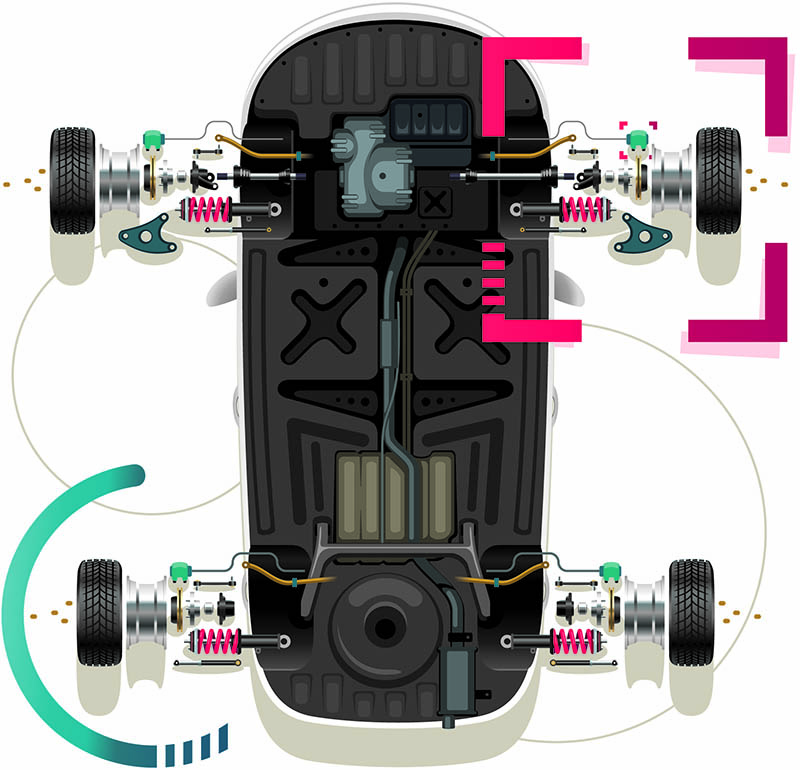

Parts Of The Car Suspension System

To understand the car suspension system, let us start by building the car from the ground up. The chassis is the main structural component upon which the car is built. Four main components make up the chassis. They are the frame, suspension system, steering system, and wheels. All four of these components work together to help your automobile absorb road forces and keep it on the road.

Chassis

The chassis is the structural or loadbearing structure that supports the car’s engine and body. The car suspension system supports the weight and absorbs the force while helping to maintain tire contact with the road. The steering system enables you to guide the car in the direction where you want to go. The axle and wheels with the road and make it possible for you to move forward.

Several different types of chassis systems exist, and they all have an effect on the car’s stability system and how easily it absorbs road forces. Each of these types of chassis has advantages and disadvantages, making it suitable for different situations. Five main types of chassis systems are:

- Ladder

- Backbone

- Monocoque

- Space

- Combination

A ladder frame is the most common type found on passenger cars because of its durability. A backbone frame is often used on sports cars because of its flexibility. The monocoque is made from molded metal and is sometimes called a unibody-type chassis. A space chassis uses welded components to create a flexible frame. Combination frames use a combination of techniques to create a balance between strength and flexibility that the car manufacturer wants.

Springs

The chassis is the main structural part of the car, but the suspension coils are one of the most important parts to help the car absorb bumps in the road and help the wheels to maintain contact. There are several different types of suspension coils and systems to help your car do this. Depending on the type of car that you have, you may have a different type of suspension coil to absorb the forces from bumpy roads. Let us explore the different types of suspension coils that you may have on your car.

Suspension Springs

A suspension spring is exactly what it sounds like. It is a heavy-duty iron bar that is wrapped around an axis. It compresses and expands to absorb the impact. The force of a bump compresses it, and then it releases this energy when it expands. The other types of suspension spring systems are based on this same principle of bending to absorb the energy and then releasing it to return to its original shape.

Leaf Springs

Leaf springs were first used on horse-drawn carriages. This was the most common type of coil until around 1985. These are made from several layers of metal that are bound together and act as a single unit. The metal bends to absorb the force and springs back into their original shape in order to release the forces.

Torsion bars

Torsion bars are a steel bar that works something like a coil. One end of the bar is attached to the suspension frame, and the other end is attached to a piece that is shaped like a Y, sometimes called a wishbone assembly. This Y-shaped piece is placed perpendicular to the torsion bar. When the wheel moves up or down from hitting a bump, this Y-shaped piece transfers force to the torsion bar. The torsion bar then twists along its axis and then springs back into place. The force of the bump is transferred to the torsion bar instead of the car and passengers.

Air Springs

Air springs work by compressing a cylinder of air that is located between the wheel and the car’s body. These are usually made of molded rubber on today’s stability systems.

Difference between sprung mass and unsprung mass. These are two terms that you will not hear often, but they are an important concept in understanding the stability system. You can think of the stability system as being comprised of two halves. The area of the car that sits on top of the axle is one part of the equation. It consists of the weight of the car, engine weight, weight of the seats, roof, passengers, and cargo.

All of these components are acted on by gravity and have weight that pushes down on the stability system. This is called the sprung mass. You can think of sprung mass as fairly constant, with only minor changes depending on the number of passengers and amount of cargo, but it is relatively the same as the weight of the vehicle.

You can think of unsprung mass as the changes in force between the road and the stability system. When you hit a hole or bump in the road, the wheel moves up or down. The force of this motion is called the unsprung mass. The amount of this force is variable and depends on the size of the bump or pothole. A larger pothole would exert more unsprung mass, and the stability system would have to compensate more than for a minor imperfection.

It would seem simple to understand how the spring or another type of spring system can absorb the mass and provide a smoother ride, but there is much more to it than that. Let us consider the difference between a sports stability system coil on a car, such as a Porsche, and a luxury stability system coil, such as a Lincoln Continental. Both of these stability systems have coils that have a different amount of stiffness.

The Lincoln has a larger stability system coil and is considered to be loosely sprung. It is a bit more flexible and able to absorb more force. It provides a smoother ride, which is what people expect from this type of car. A loosely sprung coil makes it feel like you are riding on a cushion of air, but it has a disadvantage. A loosely sprung coil means that you lose something when it comes to handling. You might have more roll in the corners. You do not expect a luxury car to handle like a sports car.

The Porsche, on the other hand, is considered to be tightly sprung. A tightly sprung car will have a rougher ride on a bumpy road. The passengers will feel it more than in a loosely sprung car. However, they have an advantage. When you brake or accelerate in a Lincoln, they do something called diving and squatting. If you put on the brakes quickly in a Lincoln, the front of the car will dip down towards the road. This is called diving. Likewise, when you accelerate, the back end of the car will dip towards the road. This is called squatting. A loosely sprung stability system dives and squats more. It is less responsive to sudden changes in road conditions than a tightly sprung sports car.

A sports car with tightly sprung coils gives you better handling and responsiveness around corners, when accelerating, and when braking, but you sacrifice the smoothness of the ride. Whether you want a coil that is tightly or loosely sprung depends on how you intend to drive it and how you expect it to ride. How the coil rides is often used in marketing a particular type of coil to a certain segment of the population based on their expectations.

You can only go so far in a sports coil in terms of the smooth ride before you start losing its handling abilities. However, the ride of the coil lacks the smoothness of the ride because the coils alone are not the only component involved in passenger comfort and handling. The coils do an excellent job of absorbing the forces, and only they tend to hold it and do not dissipate it as easily. The dampers are required to help the coils dissipate the energy and return to their natural shape.

If the coil did not have some type of damper, when it is compressed from going over bump would rapidly extend and release all of that energy at an uncontrolled rate as it returns to its original position. However, this would cause the coil to continue to bounce. It will bounce until all of the energy that was absorbed has been released. Each time it springs back and forth, it releases a bit more of the energy.

You may have experienced this if you have ever ridden in a car where the shocks are bad. You hit a bump, and you continue to bounce for some time. This type of bouncing makes it more difficult to control the car, as well as creating an exceptionally bouncy ride. The absorber system uses a process called dampening to reduce the magnitude of the vibration by dissipating it through hydraulic fluid. This causes the car to bounce less when you go over a bump. This will be explained in greater detail in the following section.

Shock Absorbers

Now, let us take a closer look inside of the shocks to see exactly how that works. The shock absorbers work something like an oil pump. It is placed between the wheels and frame. It connects to the frame and the wheel axle. This provides a flexible connection between these two points. If it were rigid, it would not be able to compensate for the changes in road height.

The most common type is a twin-tube that has a tube filled with hydraulic fluid between the frame and the axle. One slides inside of the other. The inner tube is called the pressure tube. It fits inside the reserve tube on the outside. The reserve tube is simply a storage place for excess hydraulic fluid.

When the spring hits a bump in the road, the spring compresses. When the energy is released, it is transferred to the shock absorber through the upper mount. When this happens, small orifices allow fluid to leak through as it moves up and down in the pressure tube. This is a small amount of fluid under a high amount of pressure. This fluid absorbs the energy, which flows down the piston. This resistance causes the spring to lose its energy quicker. This reduces the bounce of the car when it hits a bump.

The shock has two cycles. There is a compression cycle and an extension cycle. The compression cycles happen when the spring extends and places force on the piston. This causes the piston to move downward, which compresses the hydraulic fluid. The compression of the hydraulic fluid makes it more rigid, and it can absorb more energy. An another case is where hydraulic fluid used widely – at the brake system.

The extension cycle happens when the piston moves back towards the top of the pressure tube and compresses the fluid in the chamber above the piston. The compression cycle controls the motion of the unsprung weight of the road pressure on the spring. The extension cycle controls the heavier weight of the coil on top of the shock. It is either compressing the fluid in one part of the piston or the other. Modern absorber systems are velocity-sensitive, which means that they provide more resistance as the car accelerates. This makes them better able to respond to road conditions and suspension system motion, such as dive, squat, and sway.

Suspension Struts

Modern coils have another dampening structure to help control the balance after the spring and coils. This is called a strut. They provide an extra source of dampening. In addition to the absorber systems, they also provide support for the stability system. The shocks do not structurally support the weight of the car, but the struts do help to support the vehicle weight, or sprung mass.

It is worth mentioning that not all automobiles have struts. Some designs have separate suspension coils and shocks. Some have different systems on both the front and the rear wheels. One of the most common types of strut is the MacPherson strut, which is considered a part of the steering system. A MacPherson strut allows the wheels to move around them. The type of strut system that the car has depends on the type of handling and performance that is expected. For instance, a sports car would have a different system than a luxury car.

Anti-Sway Bars

The anti-sway bars are also known as anti-roll bars. This is simply a metal rod that joins each side of the suspension together. When you hit a bump in the road, the anti-sway bar transfers the movement to the opposite wheel and creates a more level ride. This way bar also helps to keep the automobile from rolling over when going around corners. If you are driving on an icy road and you have to correct your automobile by steering sharply, the anti-sway bar helps to prevent you from losing control. It plays an important role in stability.

Types of Car Suspension

Up to this point, the discussion of that about general suspension systems and how they work. However, your automobile has two independent systems. The front two wheels are always connected to the two different semi-axles, usually the same as how two rear wheels are connected. These are under different strains and forces as you go down the road. Therefore, different types of suspension systems are needed for the front axle and the rear axle.

Suspension systems are classed as dependent systems or independent systems. A dependent system is where an axle connects the two wheels. An independent system is where each of the wheels on an axle are allowed to move separately. Several types of these systems are to be found in different types of modern automobiles, trucks, and other cars. Let us explore the more coming front and rear suspension systems that you might encounter.

Front Suspension

Dependent front suspension.

Dependent front suspension systems are still found in some heavy-duty trucks, but they have not been found in many types of automobiles for quite some time. In this type of system, an axle connects the two front wheels. The problem with this type of system is that when the wheel hits a bump, it automatically transfers force to the other wheel and does not provide the same amount of control as if the wheels are allowed to move independently. Both wheels will feel the force and move as if both of them hit the bump. This system is not very flexible.

Independent front suspension.

With independent front suspensions, each of the front wheels moves independently from the others. This means that when one wheel hits a bump, the other one can remain stable. This gives you much better control and less bounce than a dependent front suspension.

Now, let’s take a look at some of the different types of automotive suspension systems that are available in automobiles today. Some auto manufacturers have developed their own suspension patented systems, which have varying degrees of effectiveness in creating a smooth ride. Here are some of the more common types of systems and terminology that you might encounter.

- McPherson strut. This is the most common type used in automobiles today. It was developed by Earl Macpherson of General Motors in the year 1947. The McPherson strut has a shock absorber and suspension coil that are both combined into a single unit. It is highly effective at damping. Each moves independently and provides for a lighter system than previously used dependent suspension systems.

- Double-wishbone suspension. The double-wishbone suspension is also known as an A-arm suspension. Honda motors was responsible for the development of this type of suspension system. It has several different configurations. Each wheel has a separate wishbone that is connected to the mountings. One of them is attached to the wheel, and the other is attached to the frame. The mounts on the absorber system and suspension coil absorb the vibration of the wishbone assembly. The types of suspension systems allow control over the angle of the wheel as the wheel turns and tilts in and out. These types of suspension systems also help control sway better than other types of suspension systems. This is one of the engineering design features that allow some automobiles to achieve their superior control and handling.

-

Trailing arm suspension. Trailing arm suspensions are similar to double-wishbone ones, except that the arms have been shaped to reduce the angle. The specially-shaped arms are connected to the chassis and move parallel to it. It is an older type of system that is usually associated with the VW Beetle, but some modern cars use a variation of it. Trailing arm suspensions are also found on the landing gear of airplanes.

- Twin I-beam suspension. Ford introduced the twin I-beam front suspension in 1965. It was introduced to reduce wear on parts, reduce maintenance, and improve the quality of the ride. This system uses an axle made from two rugged I-beams that share the forces of rough roads. Now, this system is seldom used, except for heavy-duty pickup trucks.

- Moulton rubber suspension. The Moulton rubber system works almost like a suspension coil spring and shock system, only the suspension coil and shock are replaced by a solid mass of rubber with specific compression properties. This system was first used in 1959. It is not used on many modern automobiles, but it is still used on mountain bikes and racing bikes.

- Transverse leaf spring suspension. This type of leaf spring suspension integrates a leaf spring with an independent double-wishbone system. It does not use a suspension coil system, and the leaf spring runs the entire width of the vehicle. This system is mounted to a subframe on the vehicle. The most common car to have this type of system is the Chevy Corvette.

Rear Suspension

Dependent rear suspension.

The rear end of the automobile does not need to compensate for steering, and you will often find a dependent rear system, combined with an independent front suspension system in some cars. Here are a few types of the most basic dependent rear systems found in automobiles today.

- Solid axle. A solid axle is about as simple as it gets. It has a leaf spring or suspension coil, mounted on both ends of the drive axle. In this system, the suspension coils are attached to the chassis itself. It is a simple system and is often used in less expensive, lower-end vehicles.

- Beam axle. This type of system is usually found in front-wheel-drive automobiles. It has a piece of metal that connects the I-beam to the opposite suspension coil mount or control arm. It is a solid set-up but does not allow for much flexibility.

- 4-Bar. This system is used on front-drive and rear-drive vehicles. Several different configurations can be found. It is generally found in high-performance sports automobiles.

- De Dion. This type of system uses a combination of a trailing arm type suspension and a solid beam suspension. It is a highly complex system with many working parts. However, it does offer superior traction and is used in many vehicles meant for off-roading.

Independent rear suspension.

Some automobiles have both front and back suspension that are independent. This means that every single wheel is mounted independently. This is why it means when you read a description of the automobile that says, “four-wheel independent suspension”. Of course, you do not have the steering rack, which makes the rear suspension a bit less complicated than the front ones. This is the most flexible type of rear suspension system.

Suspension Maintenance

Now that you understand a little bit about how a suspension system works, it should be apparent that it takes a lot of abuse during your daily drive. While struts, shocks, and other suspension parts are made to be tough and durable, they do eventually wear out. This particularly the case if you happen to live in an area where road maintenance is at a minimum.

The type of vehicle and type of suspension system also have an effect on how long your shocks and struts will last. If your shocks and structs fail, it can do more than just cause a bumpy ride. It can cause you to be unable to maintain control of your vehicle, and it can affect things such as steering, braking, and control on snow or ice. It is important to have the suspension system inspected periodically for leaks and other damage. It is a good idea to have them inspected every time you get an engine oil change or around every 10,000 miles.

During an inspection, the technician will look at various parts of the suspension, including rubber bushings and parts such as the control arm, strut rods, and other parts. They will look for cracks, swelling, wear, and general condition. They will check them for leaks. They will also perform a bounce test on the suspension. A good suspension should bounce no more than twice when you hit a small bump in the road. If it bounces more than that, it is a sign that your suspension may be failing, and it is time to have parts of it replaced.

See also: The Best Floor Jacks

You should have a basic suspension system inspection every time you get an oil change, but you should also have a more thorough inspection about every 20,000 miles. That includes the ball joints, steering linkage, free play, bearings, and wheels. It is a good idea to have your chassis lubed every time you change your oil, too.

It is a good idea to have your suspension system thoroughly inspected and necessary parts replaced before they start to fail. If your automobile suspension is beginning to show signs of wear, your car will give you a few signs. One sign is that the automobile will begin to ride rougher. If you hit a pothole and your automobile continues to bounce for quite some time, then it is an exact sign that your shocks and struts may need to be replaced.

If you feel that your car no longer corners like it used to and begins to drift towards the edge of the curve, then it is a sign that your shocks are no longer able to keep the body stable. This is particularly concerning because it could cause your vehicle to roll over when you take a corner. When you stop suddenly, if your vehicle nose dips towards the road, that is another sign your suspension system is bad. Failing to attend to this issue can affect your ability to stop, and it could cause you to have a rear-end collision with a vehicle in front of you.

Another way to tell if your absorber systems need to be replaced is to examine your wheels. Uneven wear and bald spots are a sign that your suspension may be bad because it is putting different amounts of pressure on different areas of the wheels. If you move your vehicle after it has been parked and you see spots that are located just inside where your wheels are setting, you may have a leak, which will cause your shocks to be unable to perform their job properly.

As you can see, your suspension system will give you some clear signs if it is going bad. But it is best not to wait until you see signs of imminent failure. A poor suspension system can be a hazard and could cause an accident. That is why it is important to develop a relationship with a qualified technician and have your suspension system checked on a regular basis. Keeping your car’s suspension system in good condition is the best way to stay safe and to be able to enjoy a smooth ride.