All Internal Combustion Engines require a carefully measured air/fuel mixture to be ignited at exactly the right moment for complete combustion to take place. This is no mean feat as barometric pressure changes continually, as does air temperature and engine load. Thus after years of trying to optimize engine performance by controlling the inputs alone, engineers have found an ingenious way of finely adjusting the combustion parameters by measuring the oxygen content in the exhaust gas – this is done using an oxygen sensor, also known as an O2 or Lambda sensor.

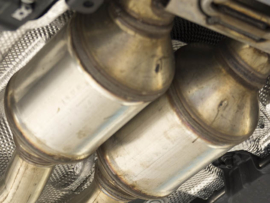

There are two types of oxygen sensor: Zirconium dioxide and titanium dioxide, with zirconium dioxide being the most common. Most modern vehicles are also equipped with two lambda sensors per system – one before the catalytic convertor, and the other in the exhaust pipe after the monolith. This is purely to monitor the performance of the catalytic convertor to make sure exhaust gas emissions are being correctly “scrubbed”.

However, even though the Lambda sensor plays an important part in optimizing the performance of the engine, it is not always easy to tell when the oxygen sensor should be replaced.

5 Symptoms of a Faulty Oxygen Sensor

Despite its critical role in the management of the engine, a defective oxygen sensor will not directly result in a breakdown – although, if left unattended, secondary problems may render the vehicle unserviceable. Some of the general signs of the oxygen sensor malfunctions are the same with other car engine sensors, like detonation sensor, but there are, nevertheless, some sure signs that the O2 sensor may have a problem:

1) The Engine Check Light Comes on

Being part of the engine management system the first signs of a problematic sensor would be the illumination of the engine check lamp. The fault would, however, have to be confirmed by using an OBD2 scanner to read the fault code.

2) Poor Performance

If the Engine Control Unit receives no input from the Lambda sensor, the system will operate as an open loop and either set a default value or ignore the input entirely. This could result in a loss of power, a rough idle, or stumble and hesitation on acceleration. An excessively rich fuel mixture for an extended period of time may eventually cause a misfire, or foul the spark plugs and “blind” the catalytic converter.

3) An Increase in Fuel Consumption

Besides the performance issues described above, a faulty oxygen sensor that causes the engine to run rich will also result in an increase in fuel consumption.

4) The Vehicle Fails the Regulatory Smog Test

An incorrectly fuelled engine will produce excessive exhaust gas emissions – to the point where the vehicle will eventually fail the emissions test.

5) The Exhaust System Emits a Toxic Smell

If a failed sensor is not attended to, the catalytic convertor may eventually be damaged. If this happens harmful gases like hydrogen sulfide – that smells like rotten eggs, sulfur, or sewer gas – will be released.

Related post: The Best Catalytic Converter Cleaners

If the vehicle displays one or more of these tell-tale symptoms it is important to take the vehicle to a professional service workshop for them to confirm the failure by way of retrieving the fault code via the OBD2 port. To simply replace the sensor based on symptoms could end up costing you money – Something like a faulty crank position sensor could display similar symptoms, leading to an incorrect part replacement.

Once a defective oxygen sensor has been diagnosed and confirmed, the next step is to replace the faulty part. But what could you expect to pay to replace the sensor: Being a fairly straightforward repair you might want to tackle it yourself – or just pay a service workshop to do the job. Both approaches have their relative pros and cons.

The Full Cost of Replacing a Faulty O2 Sensor

If you decide to carry out the repair yourself, the parts-cost can vary between $20 to $94, depending on the type and make of sensor. To have the part replaced by a mechanic would obviously add labor costs. In a recent survey of four popular franchised workshops the total replacement cost, including parts and labor, came to between $113 and $478. This wide range in pricing is due to the different costs of the sensor, and whether 2 sensors require replacing. With an average replacement cost of $138, the advantage of making use of a professional workshop is the accompanying warranty on parts and labor that ranges from 12 to 24 months.

While you’ll be paying for labor and parts at a garage, if you carry out the work yourself you will only incur the cost of the part, and possibly for an O2 sensor socket to remove and refit the sensor. One point to bear in mind, though, is that parts suppliers offer a maximum warranty of 6 months on the parts; and sometimes only a limited cover.

What is more, before attempting to remove the Lambda sensor yourself it is worthwhile to check the condition of the exhaust pipe surrounding the sensor fitting – if the pipe appears to be damaged or corroded, the replacement is best left to a professional. If the exhaust pipe breaks when you attempt to remove the faulty sensor you will be left with unexpected costs to repair or replace the effected part of the system as well.

If the area surrounding the sensor appears to be undamaged the replacement procedure is quite straightforward, and can typically be completed in under an hour.

How to Save Money When Replacing a Faulty Oxygen Sensor

The tricky part of replacing the sensor yourself is actually the initial diagnosis. While most people do not have access to the OBD2 diagnostic tool, there are a number of smartphone apps that will allow you to use your phone as an OBD2 scanner.

Before commencing work on the vehicle you may need to jack it up to easily access the sensor. If you do not have access to a hoist you need to make sure the car is safely secured on a set of trestles before attempting to crawl in under the car. Once you are satisfied it is safe to begin work, you can follow the following steps:

- Before fitting the socket to the sensor you will have to disconnect the electrical connection.

- Using the socket, loosen the sensor from the fitting.

- Once the old unit has been removed you can screw the replacement sensor in by hand, before tightening it up again with the O2 sensor socket.

- Refit the electrical connection once the sensor has been secured.

- Start the engine, making sure the check engine light is off and there are no exhaust-gas leaks from around the sensor.

- Finally, the fault code should be cleared from the ECU’s memory.

While the actual replacement is quite straightforward and inexpensive, the fact that a faulty oxygen sensor can only be confirmed via the code outputted by the OBD2, in conjunction with the warranty offered by the company you may approach to carry out the work, might just justify laying out a bit more to have the repair carried out by a good service workshop.

We do an efforts to find, research and recommend the best products. So, we may receive commissions from purchases that you make after following the links in our product reviews.