Home \ Shop \ Automotive Garage \ Impact Sockets

The Best Impact Sockets For Easy Unscrewing: Ultimate Buying Guide

Easy unscrewing of major automotive components becomes closer with proper and reliable impact sockets

- 1. Review Of The Best Impact Sockets

- 2. SUNEX 3/8" Impact Socket Set 80-piece (3580)

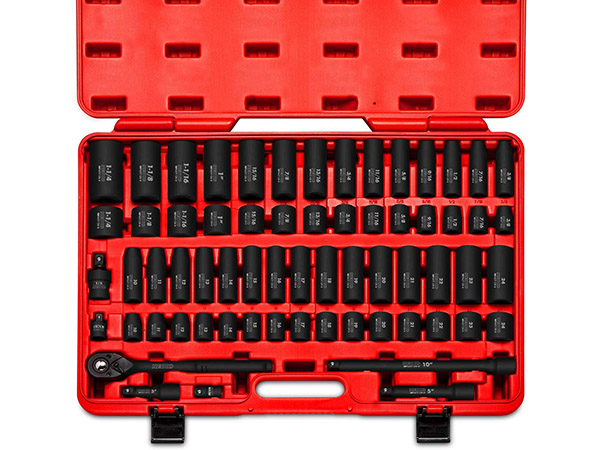

- 3. NEIKO 1/2" Impact Socket Set 65-piece (02448A)

- 4. EPAuto 1/2" Impact Socket Set (ST-015-2)

- 5. The Importance of Length/Depth/Reach of The Impact Socket

- 6. Selecting The Correct Impact Socket Drive Size

- 7. Key Features of the Best Impact Sockets

- 8. The Best Power Impact Socket Brands

- 9. What is the difference between an impact socket and a normal socket?

- 10. Are 6 or 12 point sockets better?

- 11. Is it OK to use impact sockets with a ratchet?

- 12. Standard vs deep sockets - what's better?

Driven by increasing service and repair costs, a growing number of car owners are choosing to carry out repairs at home. Weighing up the money they’re saving by so doing, versus what they would have spent had they paid to have the work done, many are deciding to invest the savings in updating their home tool kit – very often opting to replace manual tools, such as handheld ratchet wrenches with power impact wrenches.

What many DIY enthusiasts overlook when purchasing impact wrenches is that the chrome vanadium sockets that they’ve used so successfully over the years, were never designed to cope with the short, sharp shock loadings generated by an impact gun operating at a few thousand impacts per minute. Under these conditions there is a very real danger of the socket fracturing, which could result in injury.

Fortunately the solution – replacing the chrome vanadium sockets with thick walled impact sockets made from molybdenum chromium steel – is neither costly nor hard to implement. The most difficult thing is probably deciding on what impact socket best meets your needs.

After reviewing many of the products on the market, we recommend the three impact sockets below:

Review Of The Best Impact Sockets

PROS

- This comprehensive 3/8" drive 80-Piece impact socket set is ideal for the handyman or professional

- The sockets and accessories are of a high quality, and well arranged in the heavy duty storage case

- The set includes: SAE socket sizes from 5/16" to 3/4"; Metric socket sizes from 8mm to 19mm - in standard / deep / universal formats; Inverted star sockets from E5 to E16; Star sockets from T20 to T55; Universal Joint

CONS

- There really aren’t any

MAIN CHARACTERISTICS

BRAND

Sunex ToolsMODEL

3580STYLE

3/8 inchSIZE

80-pieceWEIGHT

16.96 lbPRICE RANGE

$250

Whether you’re a professional who relies on quality tools to make a living, or a DIY enthusiast over the weekend, the Sunex 3580 impact socket set is for you. The 3/8-inch drive 80-piece impact socket set comes with an impressive range of both SAE and Metric, deep, shallow and universal sockets. What is more, neatly arranged in the heavy duty storage case you’ll also find a series of Star and Inverted Star Sockets and a universal joint. One notable feature of Sunex sockets is that they have radiused edges to reduce interference with fastener’s sharp corners. This reduces the chances of damaging either the socket or fastener, while still providing a snug fit. This reduces the risk of rounding the bolt-head or nut as you apply torque.

PROS

- This functionally comprehensive, 1/2" drive 65-Piece impact socket set has everything you need. The sockets and accessories are of a high quality, and well arranged in the storage case

- The set includes: SAE socket sizes from 3/8" to 1-1/4" as well as Metric sockets from 10mm to 24mm - in standard and deep formats; 3, 5 and 10", 1/2" drive extension bars ; impact universal joint; 72-tooth, 10" long quick-release ratchet handle with 1/2" drive; 1/2 (F) to 3/8" (M) Reducer; 3/8 (F) to 1/2" (M) Adapter

CONS

- The socket set is faultless, although the blow-molded storage case doesn't live up to the rest of the set's quality standards

MAIN CHARACTERISTICS

BRAND

NeikoMODEL

02448ASTYLE

1/2 inchSIZE

65-pieceWEIGHT

34.7 lbPRICE RANGE

$200

Not only is this impact socket set well appointed, it has been well thought out: Not just a bunch of sockets thrown together in a case, but considerately paired with useful accessories. The extensive range of drop-forged, chrome vanadium, deep and shallow, six-point sockets in both SAE and metric sizes is mightily impressive. But when paired with the similarly black phosphated accessories, the 65-Piece Neiko Master Impact Socket Set, with its attention-grabbing, laser-etched markings is in a league apart from its closest competitors. While this socket set is our premium choice, it could also have been our choice for the best value-for money impact socket set.

PROS

- Deep impact sockets only – at a good price. Only pay for what you need

- The set covers most common 1/2-inch drive SAE sizes from 3/8-inch to 1-inch

- Corrosion-resistant thanks to manganese phosphate coating

- Can be considered as professional grade impact sockets

CONS

- A small kit for a limited range of applying

MAIN CHARACTERISTICS

BRAND

EPAutoMODEL

ST-015-2STYLE

1/2 inchSIZE

11-pieceWEIGHT

5.72 lbPRICE RANGE

$23

While there are many people willing to pay for all the bells and whistles of a comprehensive and high quality impact socket set, there must be at least as many that already have a normal socket set and only need the impact functionality once in a while – EPAuto has made this especially for you. The set of 11 deep impact sockets comes at a fraction of the cost of most other entries, and includes a range of SAE sockets from 3/8-inch to 1-inch – sufficient to cover most sizes if you were working on classic cars, bikes, or even some appliances around the home. Sure, this is not meant for the professional who pulls them into service a couple of times a day, and yes, you will break them with excessive force. However, at the price it’s hard to walk away from them.

With a range of types and brands of impact socket on the market, it could be difficult to choose the right one. So to simplify the process we’ve put together a guide to help you make an informed choice when selecting the best impact socket.

The Importance of Length/Depth/Reach of The Impact Socket

Short/shallow/standard reach – short reach sockets are pretty much the standard for impact sockets – much as they are with sockets used with hand wrenches. These sockets are designed to slip over the head of a standardized bolt head, or nut. The socket must however, be longer than the mating fastener to ensure there is sufficient contact for a safe transfer of the torque and shock loads.

They are cheaper than the longer reach equivalents, and in confined spaces, often easier to use. The problem is that if you have a threaded lug that protrudes way past the thickness of the nut, the short socket might not allow you to run the nut up until it seats. In these situations you will have to use a long reach impact socket.

Long reach/deep – the best long reach impact sockets are designed to reach nuts, run up on bolts or lugs, where the thread extends far past the top of the nut, thereby interfering with the socket. The extended length of the long reach socket means that the bolt, or lug’s, exposed threads will not affect the tightening of the nut. Deep sockets are commonly used for loosening and tightening lug nuts, and can even be used to tighten or remove spark plugs in an emergency – provided extreme care is taken not to damage the ceramic. Long reach sockets can also sometimes come in handy if you need to extend the reach of an extension bar.

The main disadvantages of deep sockets are that they’re usually more expensive than standard sockets, and they can also be unwieldy in confined or cramped spaces.

The other characteristic that differentiates impact sockets is the “drive”. Sockets are available in a variety of drive sizes, although the most widely used are: ¼-inch, 3/8-inch and ½-inch. Each size will require a different impact wrench and extensions.

Selecting The Correct Impact Socket Drive Size

Every impact socket has been designed to fit an impact wrench with a fixed drive size:

1/4-inch and 3/8-inch – these are not very common sizes for an impact wrench, and would usually only be required if you were regularly carrying out some form of specialist repair work. These drives usually accommodate sockets up to 13mm or ½ inch. Normally for these small drives a hand held ratchet wrench with a normal socket will suffice for any car repair work.

1/2-inch – this is the most common impact wrench size for DIY work and car repair. Whereas a 1/4-inch drive can’t transmit much torque, a 1/2-inch drive can easily be used in applications requiring 120 ft-lbs or more. When a fastener that already requires 120 ft-lbs to break it free, seizes, only an impact wrench will work – so unlike the smaller drives where ratchet wrenches can get the job done, here you will have to use an impact wrench with the appropriate impact socket. A 1/2-inch drive cordless impact wrench is all you’ll ever need to carry out most car repairs at home.

3/4-inch, 1-inch and greater – you won’t find these in most passenger car workshops. There are really very few fasteners found on a car that would require this amount of torque. Truck workshops and construction sites, on the other hand, would certainly have both hand held ratchet wrenches and pneumatic impact wrenches of this size.

Although impact sockets are all quite similar, there are some features and brands you should be on the lookout for. To make that task easier, we’ve compiled a list of things you should keep in mind.

Key Features of the Best Impact Sockets

We’ve already covered the two most important features – drive size and reach/length of the impact socket, so we’ll focus on a few other important features you might find useful:

The material used – unlike the Chrome Vanadium sockets typically used with hand ratchet wrenches, impact sockets have to withstand millions of cycles of shock loading, they are therefore usually made from Chromium Molybdenum Alloy, or Chrome Vanadium Molybdenum. Although more expensive than Chrome Vanadium, this change in material allows them to be more ductile/tough so that they do not easily fracture. However, due to the reduced hardness – about 45HRC (Rockwell), compared to 52 HRC – they probably won’t last as long.

Wall thickness of impact sockets – the walls of impact sockets should be visibly thicker than normal sockets. Not only does this mean they’re less likely to shatter, the increased mass and resultant inertia of the socket implies it can exert more force on to the fastener you are trying to loosen or tighten.

Coating – unlike standard sockets that are normally chrome-plated, impact sockets are almost always treated with iron oxide, giving them their characteristic flat or matt-lack finish. This is done because chrome plating would flake under the shock loading, while the oxide offers protection from corrosion under all operating conditions.

Warranty – a good manufacturer’s warranty is important not only to ensure the product lives up to expectations, but it is also an indication of how durable the manufacturer thinks his product is.

Comprehensive set of impact sockets – if you’re a DIY enthusiast who seldom uses an impact wrench or only uses it for a particular task, such as undoing wheel nuts, you might only need a single impact socket. However if you’re a professional you need much more than this. In this case you’ll need to consider a set of impact sockets that will come with accessories such as extensions, a universal-joint and maybe one or two long reach impact sockets.

Purchasing a comprehensive range of impact sockets also ensures that on the odd occasion you come up against an uncommon fastener size, you don’t have to stop work to go out and purchase a single socket. The cost of a set is also considerably less than buying the individual components. But before you buy, you must make sure that what is included in the set, with regards to the range of socket sizes and accessories, matches your needs.

A critical, less tangible feature that is not always easy to ascertain, is how reliable the manufacturer is. Reputable brands are built over many years, by supplying the market with reliable, quality products. Accordingly, the best way to ensure that the product lives up to the claims, is to stick with brands whose manufacturers have built up a solid reputation for delivering on their promises.

The Best Power Impact Socket Brands

These brands have a solid reputation for delivering quality products:

EPAuto – headquartered in America, this company well-known for its top-quality air filters, automotive accessories, and automotive tools, including impact sockets such as the company’s popular 1/2-Inch drive, 11-piece, long reach, impact socket set.

SUNEX – with its headquarters in South Carolina, the company was founded in 1977 with a mandate to supply the market with high quality impact sockets. One of them we are picked up as a best in general in this our review. And after 40 years of meeting those expectations, it continues to be a market leader in impact wrenches and sockets.

GEARWRENCH – from its inception in 1996, Maryland-based Gearwrench has been developing hand and power tools focused on its customers. So, while they are well known for their hand held ratchet wrenches, their affordable impact sockets (you can choose them here) are also known for their reliability.

NEIKO – manufactured in China, the tools this company supplies are on a par with most quality offerings from their American and European counterparts. That is why we’ve included the Neiko 65-Piece, 1/2″ drive master impact socket set on our list.

While we strive to provide you with a comprehensive guide to selecting the best impact sockets, you may still have one or two unanswered questions, so we’ve included a few frequently asked questions below.

FAQs:

What is the difference between an impact socket and a normal socket?

The main difference lies in their function. Impact sockets are designed to withstand impact loads without shattering, whereas normal sockets are designed for smooth torque application. As the guide outlines, this leads to differences in material, construction and protective coating.

Are 6 or 12 point sockets better?

Because 12 point sockets are less sensitive to alignment they are a little easier to work with. This is particularly true if you are working on a fastener that is difficult to see or is located in a confined space. However, the 6 point socket allows for better contact with the fastener, which in turn means you can apply more torque or shock loading without the danger of rounding the head of the bolt or the nut.

Is it OK to use impact sockets with a ratchet?

Yes, if the thicker wall of the impact socket doesn’t restrict access there’s no problem using an impact socket with any hand held wrench.

Standard vs deep sockets - what's better?

As described in the guide, it’s not really about which is better. A standard socket works equally well on a bolt-head or nut, but will not be able to run up a lug-nut if the thread extends far past the face of the nut. For this particular application you will need a deep socket that costs more but can be used on lugs that protrude past the nut, as well as normal bolt-heads and nuts.

When read in conjunction with our guide to the best impact wrench, the information we’ve discussed above, will enable you to set yourself up with the best impact wrench and sockets, to fulfil all your needs.

We do an efforts to find, research and recommend the best products. So, we may receive commissions from purchases that you make after following the links in our product reviews.

Related Products

-

Best Air Compressors For Home Garage Use in 2025 (Review)

-

Best Car Phone Mounts and Holders for Convenient Use in 2025

-

3 Best Shock Absorbers for Smooth and Precise Driving in 2025

-

Best Electric Vehicle Chargers For Home (TOP Products Review and Buyer’s Guide)

-

Best Windshield Wipers and Wiper Blades Shortlisted in 2025